Why is Industry Dissatisfied with PLM?

March 26, 2009

Product Life-cycle Management (PLM) systems have been developed and implemented since the early 1990s. Early solutions were based on a chain of application systems with proprietary user interfaces, information logistics and databases. At the turn of the century product data management standards, protocols and meta-data for application integration matured. Knowledge Based Engineering (KBE), process and collaboration capabilities were introduced. Ten years later customers are still not satisfied with the capabilities offered and value delivered by current solutions.

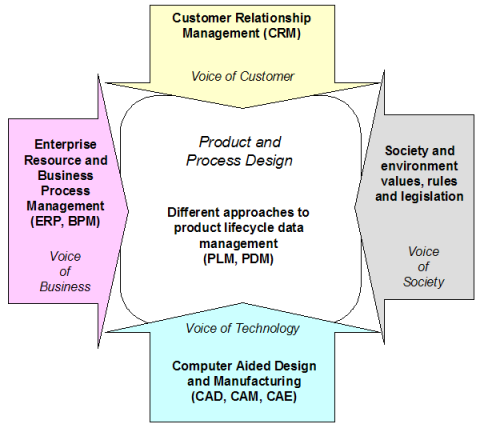

Product Life-cycle Management (PLM) systems have been built on top of CRM, CAD and PDM, or ERP, depending on who were the primary users:

Different PLM foci

Despite these efforts, support for early conceptual design and functional system design is still lacking. Communication and coordination among users is poorly supported by data exchange between application systems. Recently data hubs for sustained data management in supplier networks have been prototyped by industrial research projects. Due to their inflexibility, we believe critical design and life-cycle capabilities will still be missing. The figure below illustrates the current situation, where different islands of automation are connected by insufficient point-to-point connections.

Islands of automation

Database hubs may solve the data management challenges for most application systems, but they do not meet the needs for life-cycle knowledge sharing and reuse among different engineering disciplines, customers, partners, contractors, and suppliers.

What is Missing?

Current early design practices are in most cases supported by tools such as Word, PowerPoint and Excel. Requirements collection and analysis are in the end a question of communicating and sharing concepts, specifications, and operational experiences with customers, suppliers and other actors involved. It is critical to reach agreement on the meaning and solutions of the final set of validated requirements. The main capabilities lacking in present IT application systems, result from the way they are developed and their rigid architectures:

- Design is defining, creating and sharing data, information views, dependencies and flows, yet the applications are based on fixed meta-data and rigid interfaces for data exchange.

- Designers must be able to express their data and develop, share and cultivate knowledge. Today this is done in unstructured text and sketches, creating a discontinuity between concept development and later product engineering activities.

- Designers create many kinds of rules that must be defined and managed in work context, but today these rules are defined by IT specialists in formal languages, incomprehensive to engineers and business users.

- Design is work, where the process aspects must be captured as emergent task-patterns, not as fixed, repeatable administrative business processes.

- Designer knowledge exist as both perspective and work-centric views, yet most applications offer only minimal and superficial user interface customization capabilities.

The list of capabilities needed is longer, but our main point should already be clear: Future design platforms must support more holistic approaches, where product design is combined with organizational design, process design, and systems design. End users must be given ownership to their own data and business logic. Data models, process flows, and work logic defined by IT people are too constrained, and consequently application systems cannot support conceptual and functional system design. The majority of design data is derived from requirements and customer needs as constraints, performance parameters, design principles, features and rules. As design evolves designers must also be able to capture issues raised, experiences, and lessons learned. This knowledge must be captured in a work-centric context for automatic elicitation and reuse. A PLM architecture should create visual collaborative scenes for proactive behavior and learning-by-doing, enhancing human capabilities and creativity, creating the real-time enterprise, and transforming industrial computing to practical services and work processes.

PLM Capabilities Needed

Over the last 20 or so years we have collected these demands from industries that have experiences from PLM operations while fighting to stay competitive.

- Support requirements collection, analysis and delivery validation

- Support continuous improvement, innovation and team-learning

- Support holistic enterprise design of projects, products and work environments

- Support role-specific data and knowledge sharing, integration and reuse

- Enable concurrent design, and collaborative system and customer delivery

- Enable lean product, team, process and system design and operations

- Enable automatic adjustment of workspaces and views caused by design changes

- Enable automatic configuration and delivery of customer solutions and life-cycle services

- Exploit the web as a global knowledge sharing and work execution medium

- Exploit knowledge architectures for a holistic design approach to innovation

- Exploit active knowledge architectures for new ways of delivering computing solutions

- Exploit the holistic design approach to networked collaboration

- Transform IT systems development and industrial computing

- Transform data and information modeling to knowledge architecting services

- Transform information flow by using graphical languages and visual models

- Transform the business mindset to think in terms of knowledge spaces and roles

- Redefine the values of pragmatic work to industrial research and management

- Redefine the importance of customer-driven design of data and knowledge

- Redefine design theory to exploit role-oriented knowledge architectures and product families

- Redefine methodologies and standards to focus on evolving languages and operational methods

We need to combine the complementary strengths of computers and humans, in handling and managing data categories, object classes and product families, to provide methods for life-cycle management and reuse.

Towards a Product Knowledge Architecture

A truly concurrent, collaborative, knowledge-based PLM solution that cover all life-cycle phases, should be based on these design principles:

- Service-oriented and component-based, plugging in available IT tools in a need-driven manner,

- User-controlled, with semi-formal and interactive reasoning, because the key knowledge is the individuals’ technical design skills,

- Collaborative, because most products are too large to be designed by a chief designer, and involve too many different engineering disciplines and other business roles,

- Business-oriented, because business resources, constraints, and requirements constitute the basic framework within which the design process takes place,

- Configurable in every aspect, allowing dynamic design languages, processes, systems and services,

- Configurable on every level, allowing, capturing, and learning from local deviations, exceptions, and innovations,

- Extensible, allowing new organizational roles, working practices, system services, etc. to be brought into the joint design arena when needed,

- Based on multiple views

- Allowing each person to access the rich and complex product information structure through simplified role- and task-oriented workplaces,

- Allowing heterogeneous and inconsistent views to coexist, enabling negotiation between perspectives and shared reality construction, not enforcing a global, shared model prematurely by only allowing consistent, already interoperable, views to be expressed,

- Multi-dimensional, combining multiple type hierarchies, part structures, properties and parameter aspects, for different disciplines,

- Inter-organizational, because design increasingly requires core competence found outside of the company, among e.g. suppliers and consultants.

In summary, we must recognize the nature of innovative enterprise knowledge: The multi-disciplinary complexity of early design can only be effectively solved by developing what we call an Active Knowledge Architecture.

Where do we go from here?

In this area, we have a lot of ideas for further posts. If you find one or some of the topics below intriguing, please let us know, and we will try to prioritize these topics.

- Different approaches to product data interoperability and product knowledge sharing

- PLM needs a change of mindset, from chains of IT applications to workspaces

- PLM depends on knowledge sharing (new ways of handling data and knowledge)

- PLM is about networked operations (roles and visual workspaces)

- PLM redesigned by role-oriented knowledge architectures

- Designing a PLM architecture (who builds and what is it built from)

- A new approach to PLM solutions (splitting values and benefits)

- Building PLM networks (kinds of product projects of different business models)

- Operating and managing PLM networks (who owns what)

- PLM networking impacts on industry

- The PLM service-team organization

- Joining an operational PLM network

- Tools and methods for PLM networking

- PLM networking beyond customer delivery (visions of closing the value-chain)

- New ways of servicing customers

- PLM for project and product families

- PLM and design lifecycles

Or propose additional topics!

March 19, 2010 at 20:34

[…] 2010 A co-worker passed along a valuable article from the Active Knowledge Modeling blog entitled “Why is Industry Dissatisfied with PLM?” by Frank […]

March 26, 2010 at 03:14

[…] listening on Google” research and shout “PLM dissatisfaction” search. The article with a complete match to my criteria came in the beginning – “Why is Industry […]